-

- Downloads

added initial results

Showing

- README.md 41 additions, 1 deletionREADME.md

- img/emboss-today_101st.jpg 0 additions, 0 deletionsimg/emboss-today_101st.jpg

- img/mfg_100_tests.jpg 0 additions, 0 deletionsimg/mfg_100_tests.jpg

- img/mfg_press.jpg 0 additions, 0 deletionsimg/mfg_press.jpg

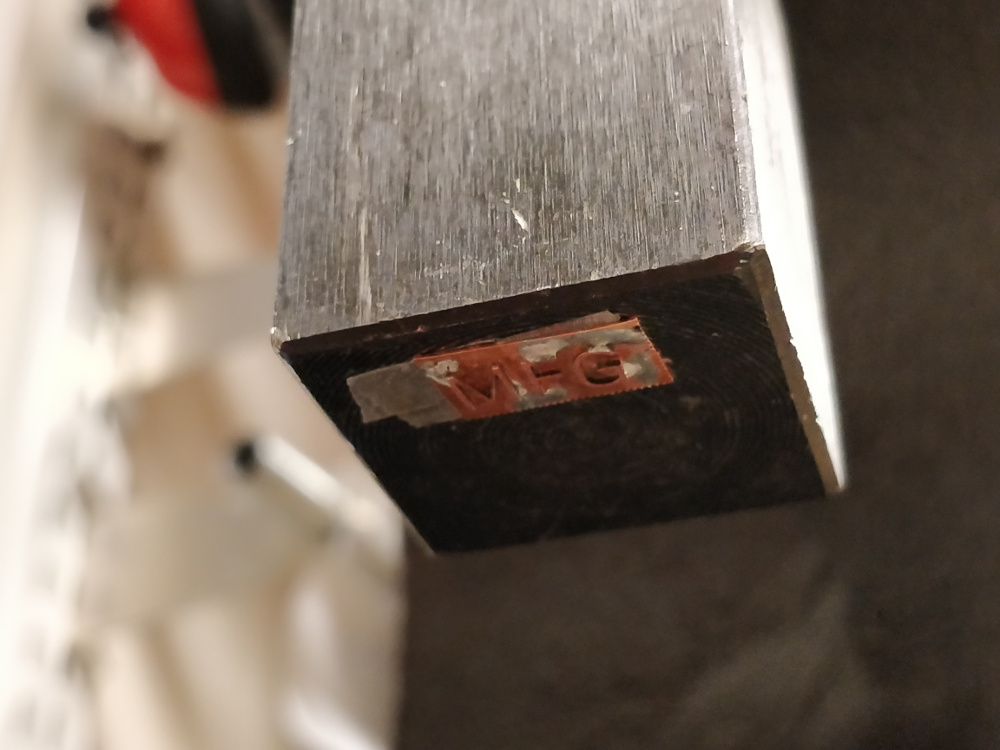

- img/mfg_tool.jpg 0 additions, 0 deletionsimg/mfg_tool.jpg

- img/oxfording.mp4 0 additions, 0 deletionsimg/oxfording.mp4

- img/tool_deburr.jpg 0 additions, 0 deletionsimg/tool_deburr.jpg

- img/tool_in_oxford.jpg 0 additions, 0 deletionsimg/tool_in_oxford.jpg

- img/tool_soldered.jpg 0 additions, 0 deletionsimg/tool_soldered.jpg

img/emboss-today_101st.jpg

0 → 100644

260 KiB

img/mfg_100_tests.jpg

0 → 100644

360 KiB

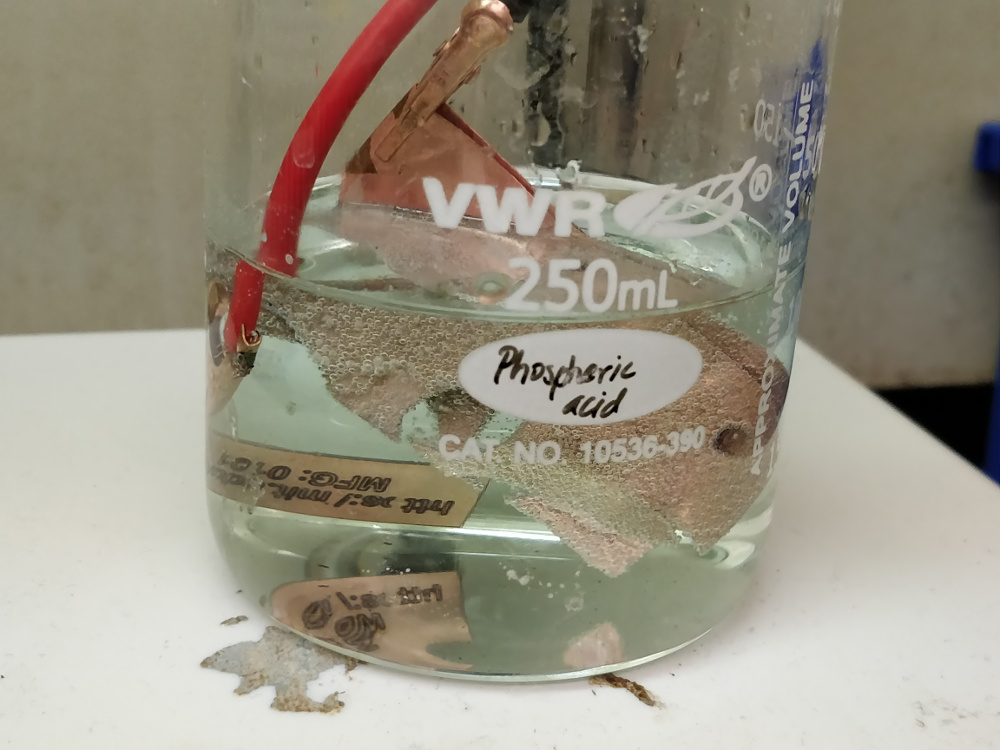

img/mfg_press.jpg

0 → 100644

515 KiB

img/mfg_tool.jpg

0 → 100644

176 KiB

img/oxfording.mp4

0 → 100644

File added

img/tool_deburr.jpg

0 → 100644

194 KiB

img/tool_in_oxford.jpg

0 → 100644

228 KiB

img/tool_soldered.jpg

0 → 100644

205 KiB