Beams for Machines

Torsion ain't easy, as they say. In a break from a bonafide software extravaganza, I've been walking through this design for a decent beam from flat stock, to back on RCT Gantry types.

The beam design is straightforward, but I've also been occupied with joinery. A big driver here is the desire to make machines with laser cutters and acrylic, to really lower the threshold for fab-your-own-machine-ing. To that end, joints in acrylic that don't cause cracking has been the order.

- Typically, laser cut acrylic members are joined a-la this classic machinescrew-and-captured-nut joint:

-

pic of makerbot type joint ~

- These are overdue to crack at the stress concentration around the nut:

-

microscope pic of your nut beam ~

This is largely the fault of Acrylic, which, despite its low cost, relative high stiffness (~ 3GPa Modulus), and ease-of-lasercutting (about 50W machine can chew through 7mm OK), is very brittle.

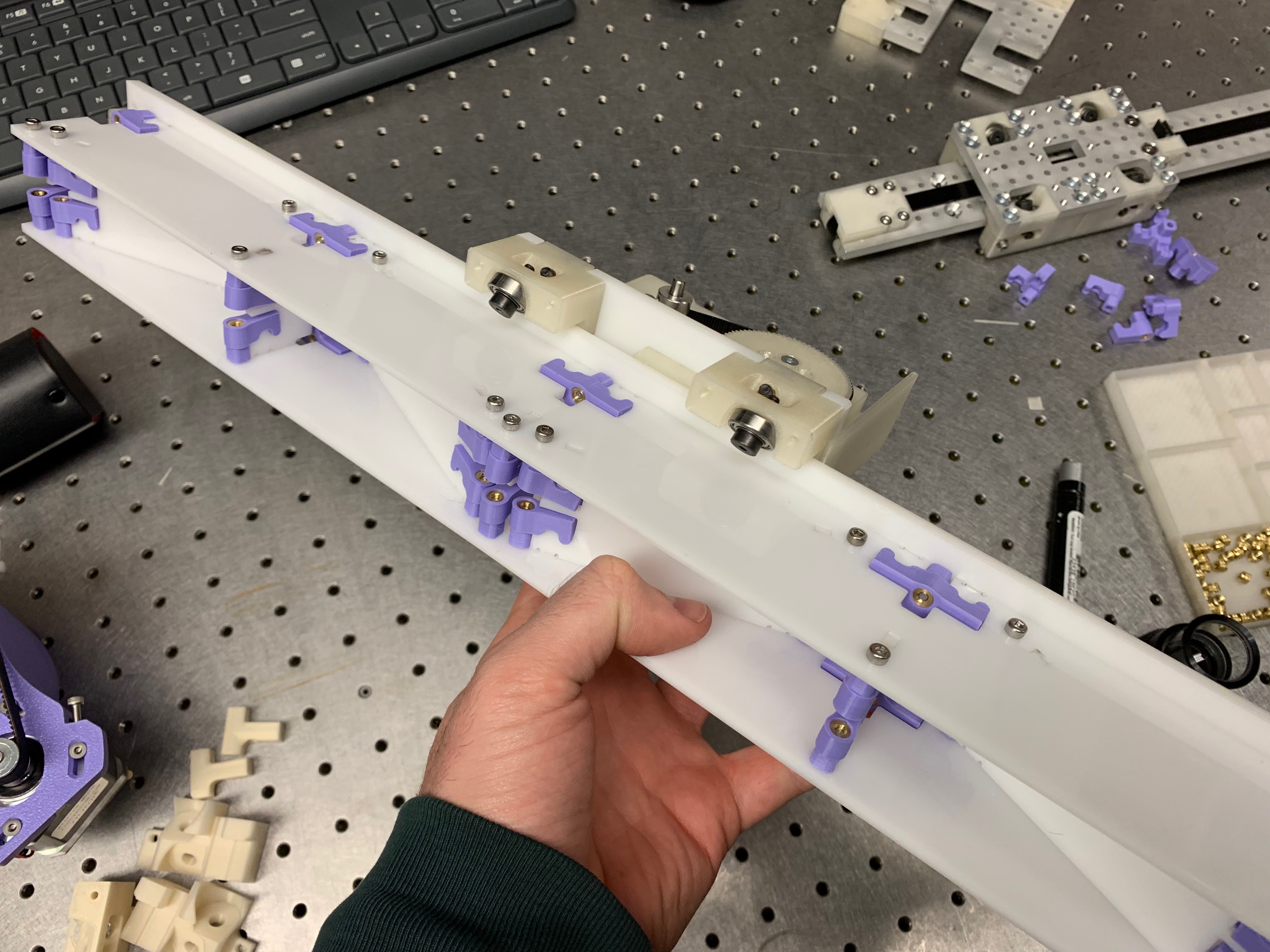

- To handle this, I was interested in developing some 3D Printed load-distributing members. I went through a few designs, settling on something like this:

-

pic of joint ~

There are 'singlet', 'tee' and 'corner' members, each having a heat-set insert in the rear, and some arms to grip the reciprocal laser-cut feature. I'm a minor fan of these so far, but I think the design can still be improved. In general, I'd love more algorithmic generation - a mechanically sound method for generating 3D Printable 'node' joinery based on pin-frame beams is a bigger desire.

Beams made up of these joints feel pretty satisfying, although the subtle 'creak' of the acrylic tells me they're not 100% quite yet. However, serviceable.

Usage

Material choice

Like I mentioned, these are sort of designed with Acrylic in mind. That said, moving to Delrin (Acetal) will up the overall durability for a similar modulus, but also double your cost.

Moving to aluminum will similarely double your cost, and put you in a new fab-bracket (I use a waterjet), but brings your beam from 3GPa material -> 60GPa (also ~ 2.5x density). With aluminum, this stress concentration issue isn't so controlling, and the 3D Printed joint effectively adds a relatively-spongey moment in the structural system, so, with complete time, different joinery should be developed for metals. Alas, it'll do as is.

Be careful about

- thicknesses: the 3D Printed joints are much happier going together if the arms are dialed in to pinch on to laser cut members, so if you're going to assemble lots, test a pair first

- beams on pulley'd axis: there's not room (at the moment) to accomodate for the pulley's return path. when I spin these through CAD->CAM, I add that accomodation manually (in Rhino). this is much easier with wider beams, as is planned for the little rascal machine.

Doing it

Apart from that, download the .f3d model (should be in this repo, when the update comes), set your parameters, and las / print.

My workflow is like this:

- make parameters for material thicknesses in beam, and gantry model

- export both .step

- (if a pulley) bring both into rhino, modify ears to suit, and add pulley allowance to beam webs

- las / wj / 3dp