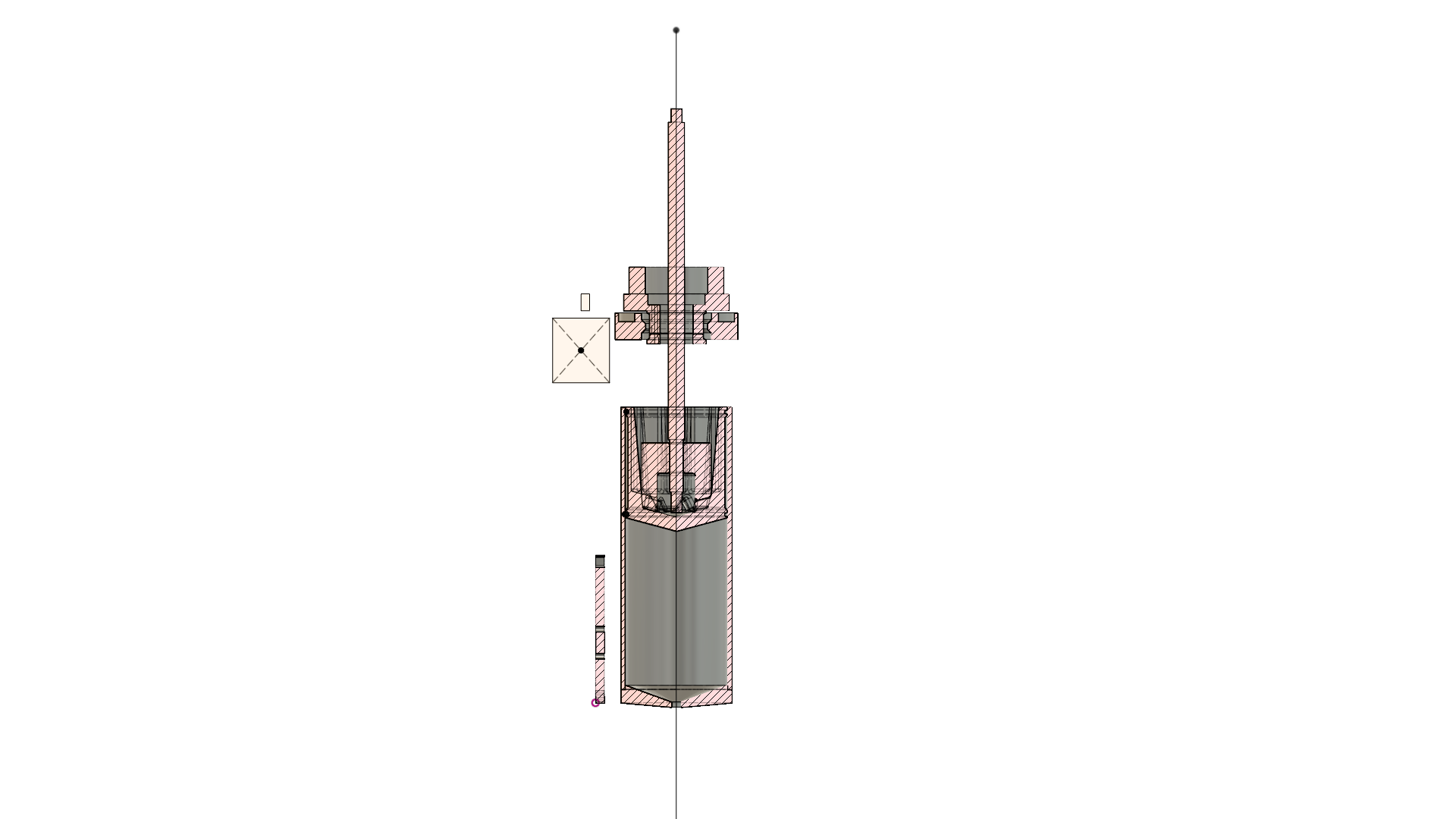

# With Gusto! Today I'm designing a clay extruder. I've taken [one pass at this](https://gitlab.cba.mit.edu/jakeread/claystack) before, so I know a bit more about what I'd like to see in the end result: clay should be easy to load, straight-up plunging the clay is mechanically arduous, but worth it I want to strong arm this whole situation. The mud will fear my plunger. From the supply chain I'm going to pull a few critical components: closed loop gt2 for first reduction bicycle headset bearings to mount a ballscrew nut, driving a ballscrew nema 17 motor & 20 or 16T pinion pulley I'll use 2.5" ID polycarb tubes to load clay in to, with 12" (off-the-shelf length) sections, assuming 8" used height, that's about 3.5lbs of clay, which is plenty much. ## 1kg Carry or Tube Delivery My first temptation is to just carry this whole thing around the machine. The laying-down is speed-limited by the process, not by the machine's accelerations... so carrying 1kg on the end of the machine is OK. It's also straightforward, and has a kind of elegance that's hard to find with tubes. I *am* a bit weary of doing this to the plastic parts of my [gantries](https://gitlab.cba.mit.edu/jakeread/rctgantries/). To that note, I'll also spec parts to design / build a 'bowden' type nozzle delivery... Since size will be a bonus there, I'll pick some ... 1/2" id hose and compression fittings. My notes from before: ```We found that with ~ 20% water added, we could push it through a 1/4" inside diameter tube having ~ 1m of length with only 30psi.``` So, straight up clay (no water), anticipating a similar (hopefully shorter) hose length ... 1/2" ID seems OK, considering the force (that I haven't actually calculated yet) that we should be able to plunge with. ## Design Log Here's the stick at June 7 2019  Ok, through some of this ... - nozzle detail ... o-ring, and screw-to-secure, or secure somehow ? - finish motor mount to pulley side - consider similar structure & method (alu tabs with 3dp heatset inserts to secure) for bottom lock-in ... - plate - fin - luer lock - vol / step ? haha - ballscrew: flip flange side, - instead of an o-ring seal, use dam-type flange wall? - or o-ring gets a nest, for slightly oversized o-rings ? ## The McMaster Order - 8585K31 1/8" Wall 2.5" ID Polycarb Tubes - 9558K75 O-Rings - bowden-type hose fittings ... barbs? - 50915K324 Compression Fitting 3/8" and 3/8" - 50915K195 Compression Sleeves - 50915K169 Compression Elbows (for turnaround possibility) - 4568K135 Turnaround Pipe